How Penetrant Testing (PT) Works

Penetrant testing, also known as PT, is a non-destructive testing method for detecting surface defects in non-porous materials. Typical materials include: aluminium, magnesium, titanium, stainless steels.

-

Step 1 – Preparation

Clean the surface to remove dirt, oil, and residues.

-

Step 2 – Apply Penetrant

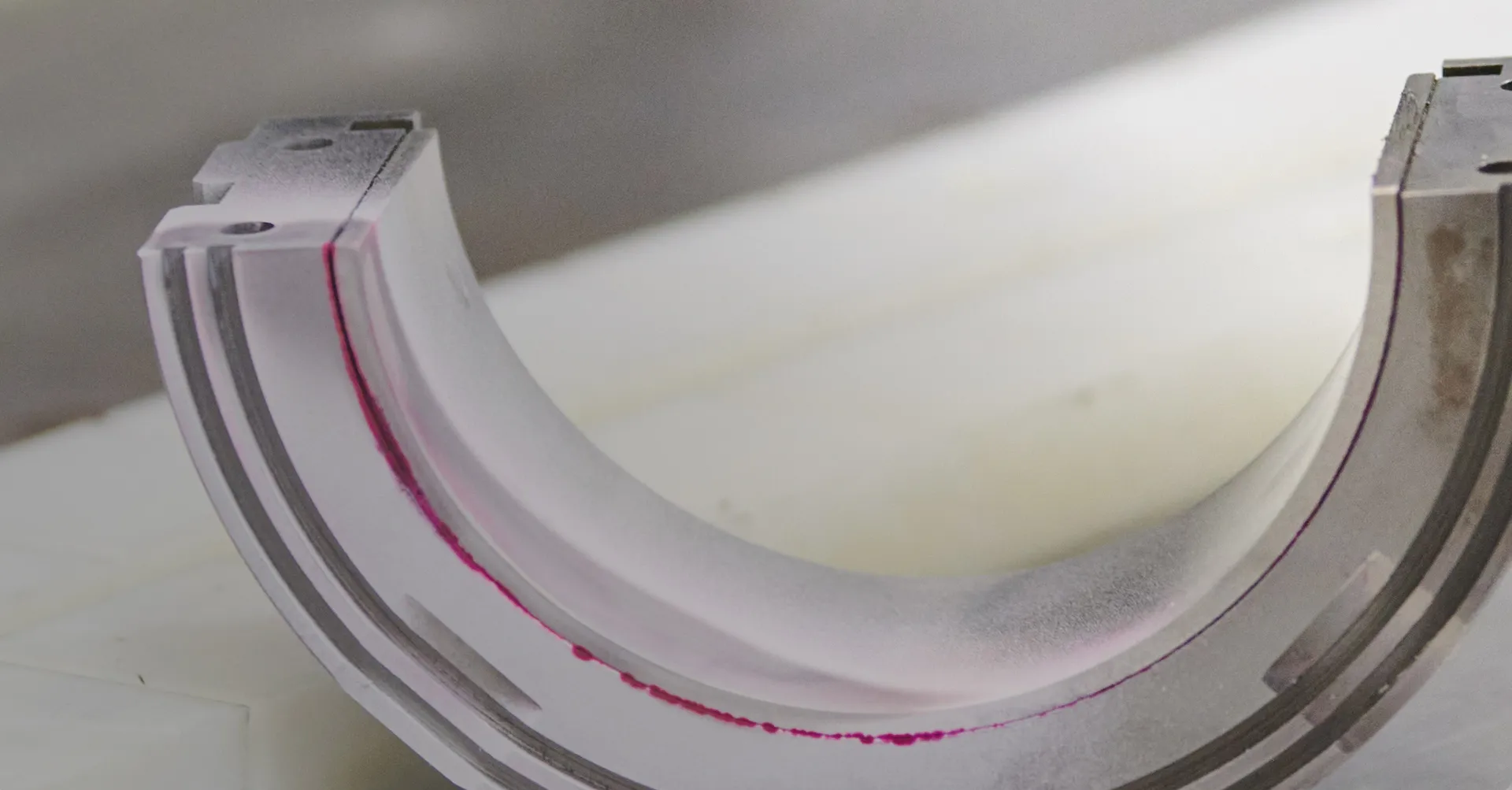

The red or fluorescent liquid is applied and penetrates any defects.

-

Step 3 – Intermediate Cleaning

Remove excess penetrant without flushing it out of the defects.

-

Step 4 – Apply Developer

Apply the white developer, which draws the penetrant from the defects to the surface.

-

Step 5 – Evaluation

The defects appear clearly visible. For fluorescent methods, evaluation is performed under UV light.

-

Step 6 – Final Cleaning and Documentation

After evaluation, clean the component and record the results.

- Red-White Testing – for simple and quick visual inspections

- Fluorescent Testing – particularly sensitive, ideal for safety-critical components

Penetrant testing is cost-effective, flexible, and delivers reliable results even for complex geometries. It is one of the most important methods in non-destructive testing.