How Hardness Testing (HT) Works

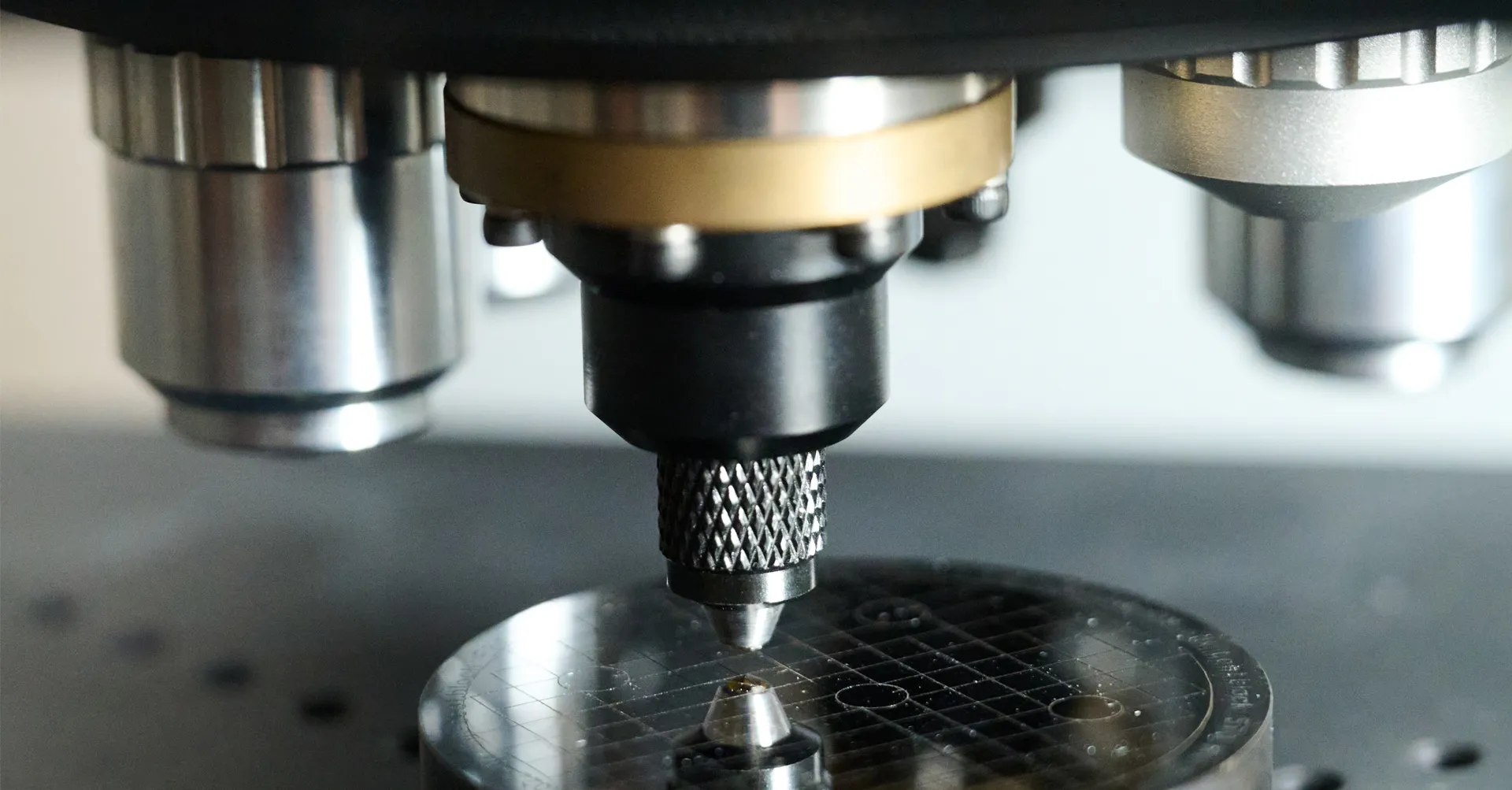

hardness test according to Vickers

Hardness testing determines the resistance of a material against the penetration of a test body or against plastic deformation. It correlates with strength and wear behavior and is therefore a central quality characteristic in production and maintenance.

-

Step 1 – Sample Preparation

Clean the surface and – depending on the method – grind/polish flat. For mobile methods (Leeb/UCI), a metallically bright, load-bearing surface is usually sufficient.

-

Step 2 – Indenter / Test Force

Depending on the standard, diamond pyramid (Vickers), diamond cone or ball (Rockwell) or carbide/steel ball (Brinell) are used. The test force is applied according to the standard.

-

Step 3 – Impression Measurement

Measurement of diagonals (Vickers), impression diameter (Brinell) or permanent penetration depth (Rockwell). For Leeb, the rebound velocity is measured; for UCI, the frequency shift of a vibrating rod.

-

Step 4 – Evaluation & Documentation

Calculation of hardness value (HV, HBW, HRC/HRB, HL) and creation of a standardized test report including measurement location. Optional: hardness profile diagrams and limit value assessment.

- Vickers (HV) – DIN EN ISO 6507-1, universal from very soft to very hard, small test areas and layers

- Brinell (HBW) – DIN EN ISO 6506-1, ideal for coarse-grained/softer materials, castings and non-ferrous metals

- Heat treatment verification (SHD/RHT, Nht)

- Weld seam and HAZ evaluation

- Incoming goods and production control

- Hardness profile tests on surface layers

- On-site component testing (turbines, shafts, molds, gear parts)

We advise you on the selection of the suitable method and provide reliable results for your quality assurance – fast, transparent and accredited.