How the Tensile Test Works

Stress-Strain Diagram

The tensile test measures the mechanical load capacity of a material by controlled elongation of a standardized specimen until fracture. Force and elongation are recorded to create a stress-strain diagram.

-

Step 1 – Specimen preparation

Preparation and measurement of the specimen according to standards to ensure reproducible results.

-

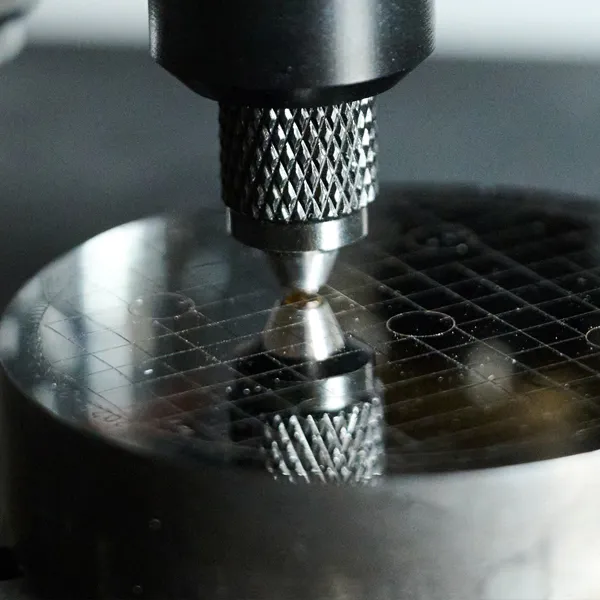

Step 2 – Clamping the specimen

The specimen is clamped into the testing machine and checked for correct alignment.

-

Step 3 – Loading until fracture

The specimen is elongated at a defined speed while force and elongation are continuously recorded.

-

Step 4 – Evaluation & Test Report

Determination of tensile strength, elongation and yield strength and preparation of a standardized test report.

- Quality control of metallic materials

- Acceptance testing of components and welds

- Research and development of new materials

- Comparison of material batches and suppliers

We support you in selecting the right testing method and provide precise results for your material testing – fast, reliable and accredited.