Ductility in Practice: Test Procedure & Evaluation

In the tensile test, a standardized specimen is loaded until it breaks. We continuously record force and elongation, determine the stress-strain diagram, and calculate all key values (Rp0.2/Re, Rm, Ag, A). Optionally with photo documentation of the fracture surface and temperature control according to standards.

-

Step 1 – Samples & Identification

Manufacture/receipt of standardized specimens, unique ID, set measurement length (Lo).

-

Step 2 – Testing

Time-strain rates & test speed according to standards, continuous recording, optional extensometer.

-

Step 3 – Evaluation

Determination of Re/Rp0.2, Rm, Ag, A; diagram and limit value assessment in the test report.

-

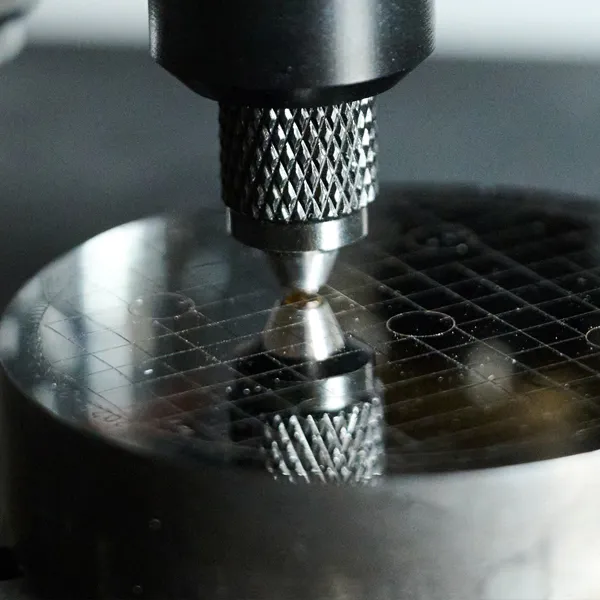

Step 4 – Supplementary Tests

For brittle behavior: Charpy impact test. For case hardening and gradients: hardness testing.

We advise you on selecting the appropriate test program and deliver reliable results for your quality assurance – fast, transparent, and accredited.