How the Charpy Impact Test Works

In the test, the pendulum hammer strikes the specimen at its lowest point at the notch. Part of the impact energy is used to fracture the specimen – this impact energy (in joules) is measured. From the results, the tendency to brittle fracture, toughness, and temperature dependence can be derived.

The temperature dependence is particularly pronounced in steels with a body-centered cubic (bcc) crystal structure: within a narrow temperature range, the impact energy drops sharply from high to very low values. By tempering (± 0.2 °C), we can precisely determine the transition temperature.

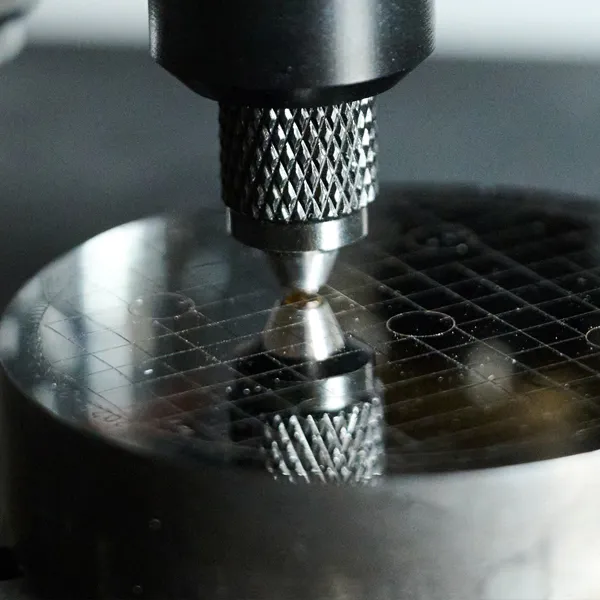

The specimens are manufactured according to DIN EN ISO 148-1 and prepared in the laboratory with a V-notch. This ensures reproducible and standardized results.