How Metallography Works

Specimen preparation

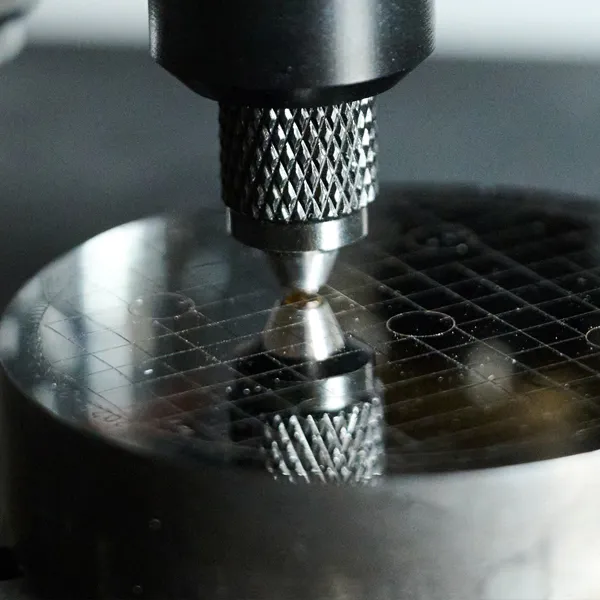

The specimens are taken from the component and prepared by grinding, polishing and etching. Only through these steps does the microstructure become visible.

Under the microscope, we analyze microstructure types, grain sizes and coating thicknesses. With digital image analysis, distributions, sizes and types can be determined precisely – e.g. graphite types in cast iron.

The results are documented in a digital test report and provided to you for evaluation.