Technical fundamentals of Phased Array Ultrasonic Testing (PAUT)

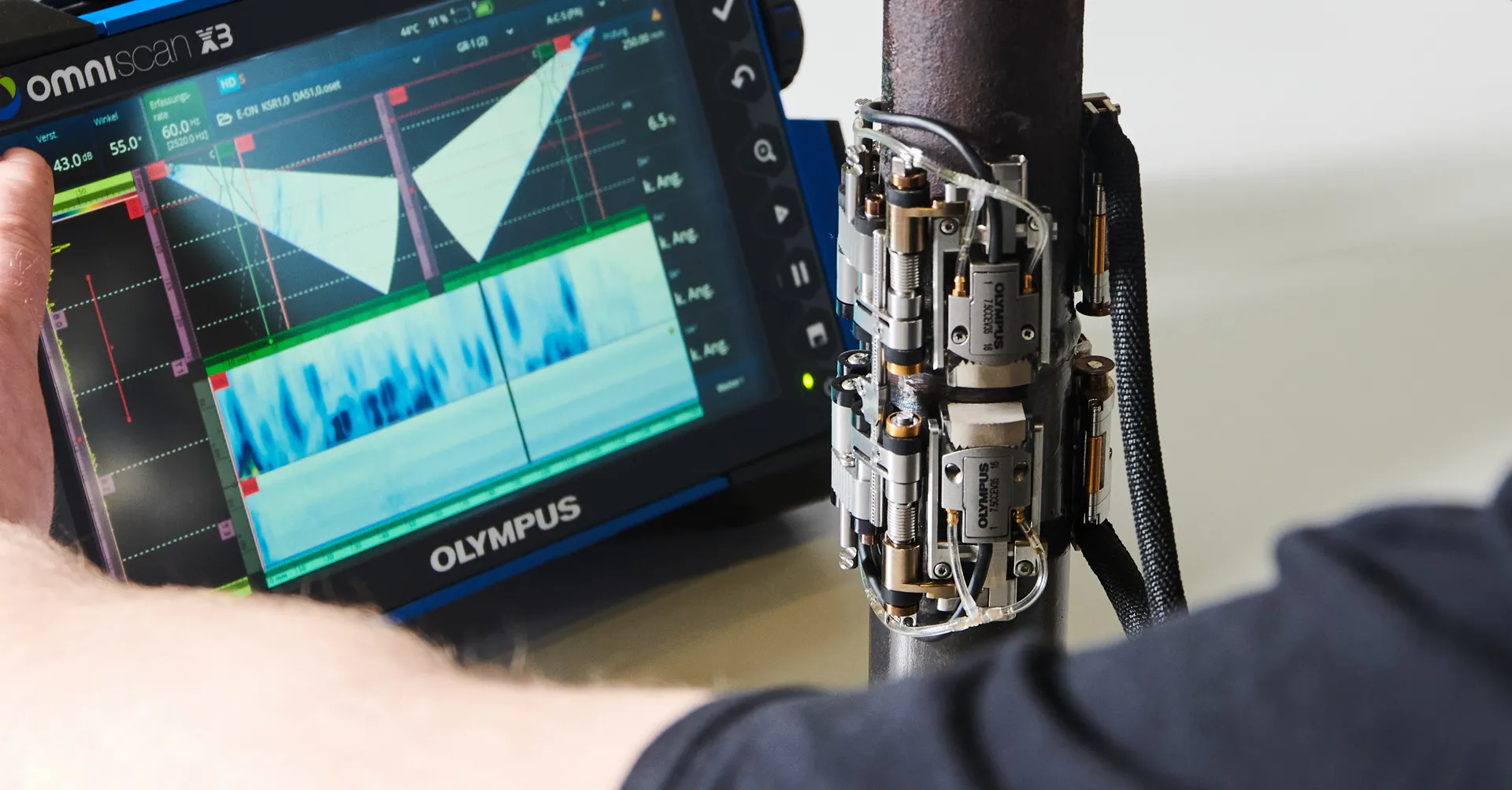

In Phased Array (phased array technology), the individual elements of a multi-channel probe are excited with phased time delays. These delays allow electronic control of angle, focal depth, focal length and beam diameter of the sound field. Echoes from a desired focal point are received coherently with corresponding delays — resulting in high-resolution S-, B-, and C-scans.

- Faster area coverage through electronic beam steering

- Higher detection sensitivity via dynamic depth focusing (DDF)

- Imaging representation for thorough evaluation & documentation

- Better adaptability to complex geometries

Electronic linear scan (linear scan): An active element group shifts the aperture along the sensor axis — ideal for fast, parallel area coverage.

Sector scan (angle scan): The sound beam is swept over an angular range; focus & excitation conditions are definable — preferred for weld inspections.

Dynamic depth focusing (DDF): Real-time adjustment of delay and gain on reception — improves signal-to-noise ratio and detection sensitivity throughout the thickness.

We use angle beam sensors, 2D/1.5D sensors, and S/E sensors — depending on component geometry with delay wedges, in contact or immersion technique. The active aperture (A) of a linear sensor is given by A = (n‑1)·p + e (n elements, p pitch, e element width) and significantly determines resolution & penetration depth.

PAUT provides S-, B-, and C-scans with color-coded amplitude display. All results are digitally recorded and compiled in a tamper-proof test report — including image evaluation and assessment criteria.

Mirror effect for wall and coating thickness measurement

The so-called mirror effect records ultrasonic echoes between the front and back walls of a component. The time difference of these echoes enables precise determination of wall or coating thickness.

This method is especially useful for corrosion inspections, monitoring of pipelines, inspection of vessels, and components with coatings. Thanks to the imaging capability of Phased Array, even complex geometries can be reliably evaluated.

The choice of scan mode depends on geometry, material and objective. The overview shows common settings in practice.

| Mode | Typical application | Advantage |

|---|---|---|

| Linear‑Scan | Semi-finished products, plates, profiles; area coverage | Fast & reproducible |

| Sector scan | Welds on pipe/vessel; angle range | Volume coverage & angle flexibility |

| DDF | Varying thickness; fine defects over depth | High sensitivity over full thickness |

| Immersion technique | High-resolution analytics; complex contours | Very high resolution, uniform coupling |