How Spectral Analysis Works

OES & XRF

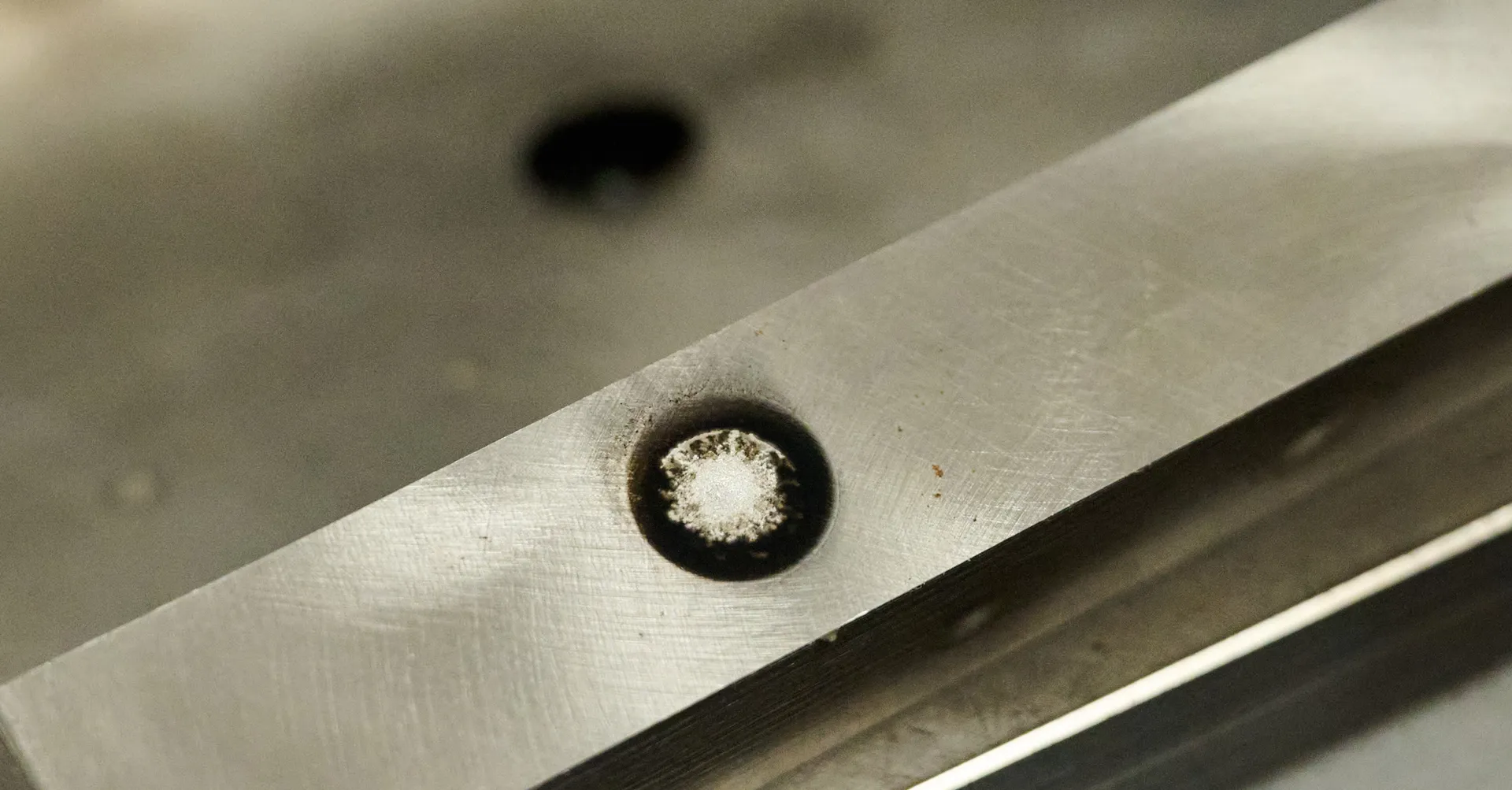

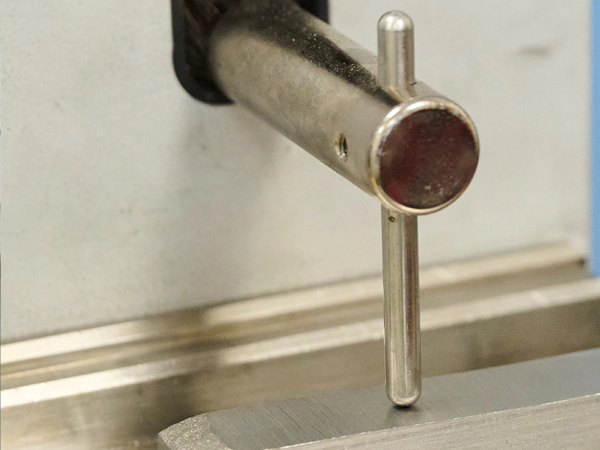

In OES analysis, a small part of the sample surface is vaporized by an electrical discharge. The resulting plasma contains the alloying elements, whose specific emission lines are measured and evaluated.

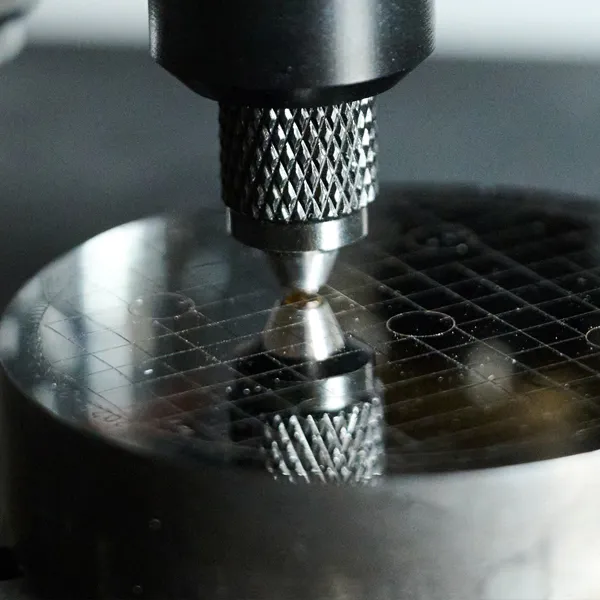

The spectrometer separates the light into its wavelengths using a diffraction grating and measures the intensity. This determines the percentage composition of the elements.

In XRF, the sample is excited with X-rays. The emitted characteristic radiation also allows precise element analysis – especially for alloys and coatings.

The results are digitally documented and provided in a test report.